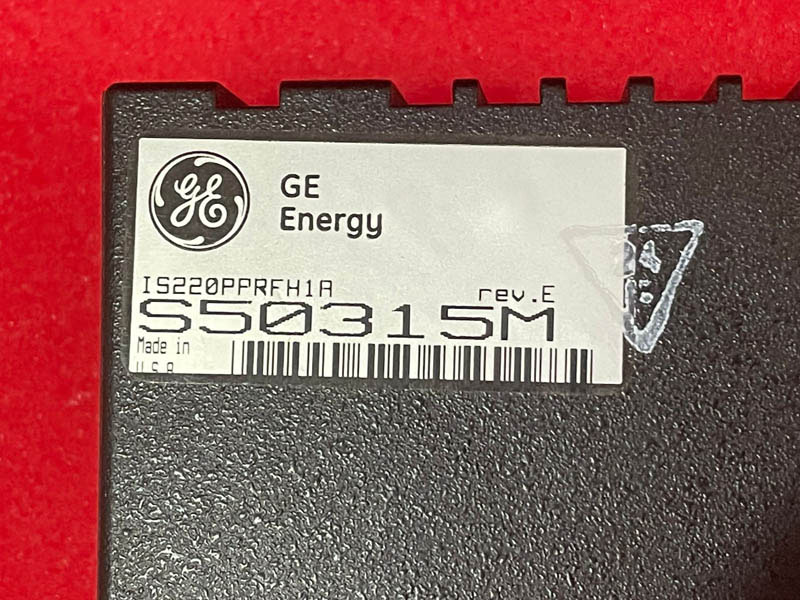

GE IS220PPRFH1A PROFIBUS Master Gateway Pack

Description

| Manufacture | GE |

| Model | IS220PPRFH1A |

| Ordering information | IS220PPRFH1A |

| Catalog | Mark Vie |

| Description | GE IS220PPRFH1A PROFIBUS Master Gateway Pack |

| Origin | United States (US) |

| HS Code | 85389091 |

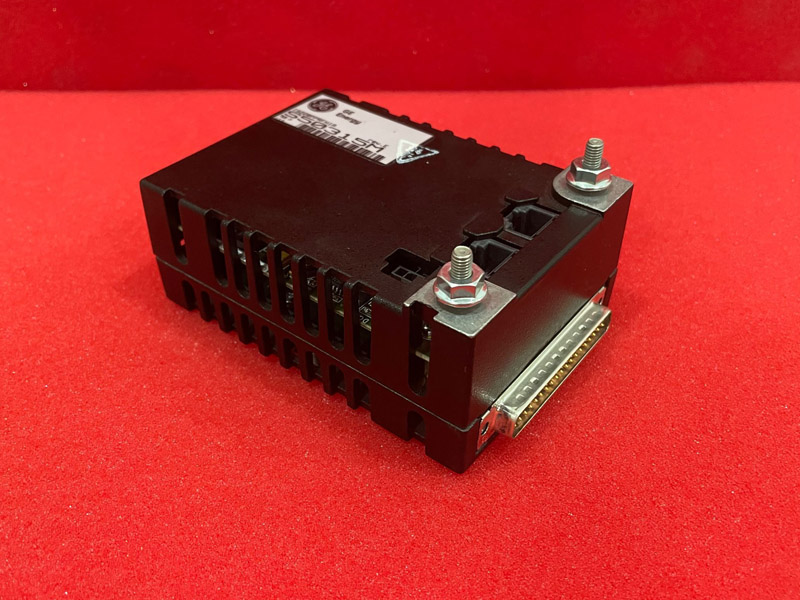

| Dimension | 16cm*16cm*12cm |

| Weight | 0.8kg |

Details

The IS220PPRFH1A is a PROFIBUS master gateway module developed by GE and is part of the Mark VIe series. This module is used to map the I/O data of PROFIBUS slave devices to the Mark VIe controller of the I/O Ethernet and is a PROFIBUS DPV0, Class 1 master device.

The IS220PPRFH1A provides a PROFIBUS RS-485 interface through the COM-C PROFIBUS communication module from Hilscher GmbH, using a DE-9 D-sub interface connection. As a PROFIBUS DP master, the module supports a transmission rate range from 9.6 KBaud to 12 MBaud, can connect up to 125 slave devices, and each slave supports up to 244 bytes of input and output data.

Like other I/O modules, this module uses a dual Ethernet connection configuration. In hot standby mode, two PPRF modules can be configured, one as a master station to communicate with the slave station, and the other as a standby station, ready to take over the master station function when the master station fails, thus achieving system redundancy.

Features:

The IS220PPRFH1A supports a variety of redundant configuration options, which improves the reliability and stability of the system, including:

One I/O module is equipped with one Ethernet connection (no redundancy).

One I/O module is equipped with dual Ethernet connections.

In hot standby mode, two I/O modules are used, one as an active master station and the other as a standby master station.

The IS220PPRFH1A is mainly used in GE's Mark VI series control systems, especially for automated drive systems for gas turbines, steam turbines and wind turbines.

These control systems are used to handle complex industrial applications to ensure efficient and safe energy production. Before the Mark VI series, GE's Mark V series control system only supported gas turbine and steam turbine applications, while the Mark VI series further expanded the application range to support wind turbine control, improving the flexibility and compatibility of the system.

The use of the IS220PPRFH1A PROFIBUS master gateway module helps achieve efficient connection and data exchange with the PROFIBUS network, allowing the Mark VI control system to better support different types of industrial equipment and process control, provide powerful communication capabilities and redundant backup functions, and ensure that key systems can maintain stable and reliable operation under various working conditions.